EDEN PRAIRIE, MN — If you are a sauce producer, regardless if you make barbecue, hot sauce or a gourmet dressings, making delicious tasting product is not just the question — it also involves efficiently getting your product into a container and to retail. If you are selling bbq sauce or hot sauce, a sauce bottling machine could be the game changer for your business. We will dive into the equipment specification benefits and how it fits your business need.

A huge uptick in production speed

A sauce bottling machine how it keeps pace with the high volume demands? Processing between 20 and 120 bottles per minute, these machines are capable of working with a wide variety of sauces depending on their viscosity and bottle size. This is far different than the slow, labor-intensive process of bottling manually. Scaling the operations becomes much more accessible when this end of your production line speeds up.

Dependable Verification and Reliability

Another sign of sauce bottling machine use is exactness in filling each bottle to its pre-determined level. This class of machinery delivers the right product volumes per bottle - an absolute necessity to ensure consistent product quality and a significant reduction in waste. Product volume is important because there are packaging regulations, (see this post) and the fact you do not want to have angry customers that keep the swearing up.

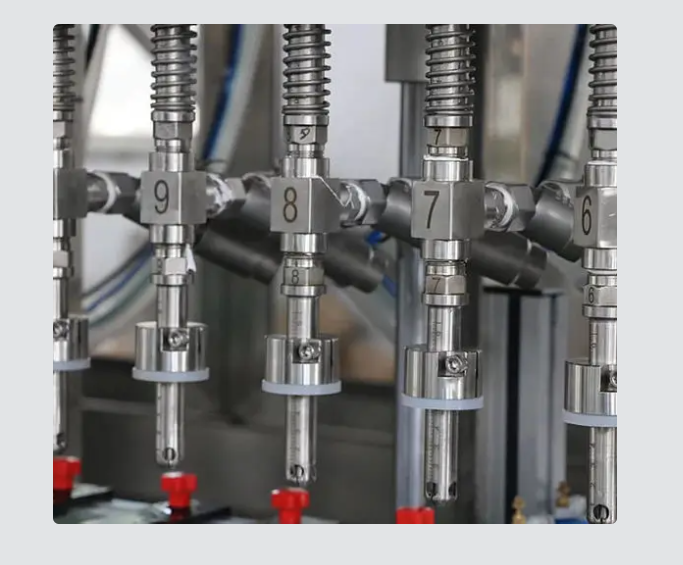

Works with a Variety of Sauces and Bottles

The singular feature of contemporary sauce bottling machines is their versatility. They can manage any sauce, and achieve a level of consistency in ranging from thin and flooding to thick and chunky, without losing in throughput or accuracy. They are also adjustable so they can fill a variety of sizes and shapes of bottles to meet market demand or a unique packaging application.

Enhanced Operational Safety

The use of an automated bottling system reduces the possibility that employees will be injured by handling packaging and unloading hazardous chemical bottles. This also helps protect workers by reducing the amount of manual labour required to fill the bags and all but eliminating irritation and exposure to hot ingredients, increasing overall workplace health and safety.

Long Term Cost Efficiency

Buying a sauce bottling machine may seem pricey, but in the long run, it only brings savings. More efficiently manufacturing the product allows the product to be produced with less labor and less product waste. In short, automated bottling can also help to enhance your brand reputation, and hence sales, from an impact and consistency viewpoint.

A well-designed sauce bottling machine integrated into your production eliminates not only the stress of hiring people but also adds a seamless assembly line that improves the production process and increases overall growth. For those looking to scale out their product, increase throughput or simply make their product more consistently, this technology provides a powerful tool. There are many reasons why sauce producers should invest in a sauce bottling machine in order to scale up operations, and improve efficiency, in fact.